Design control is a critical aspect of the product development process, particularly in engineering and manufacturing industries where the quality and integrity of the final product are of utmost importance. A well-defined design control process ensures that products are designed, developed, and released in a controlled and systematic manner, minimizing risks and ensuring compliance with industry regulations and standards. In this article, we will discuss the must-have features of a good design control process from an engineering perspective.

- Documented Procedures: A good design control process should have documented procedures that outline the steps, responsibilities, and requirements for each stage of the product development process. These procedures provide a clear roadmap for the engineering team to follow, ensuring consistency and repeatability in the design process.

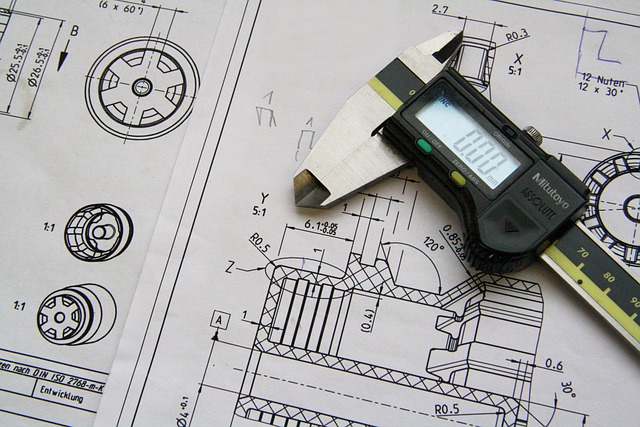

- Design Inputs and Outputs: A design control process should clearly define the inputs and outputs of each stage of the product development process. Design inputs include customer requirements, regulatory requirements, and other specifications, while design outputs include design documents, drawings, and specifications. Clear documentation of design inputs and outputs ensures that the product is designed to meet the intended requirements and specifications.

- Design Reviews: Design reviews are critical checkpoints in the design control process that involve a thorough evaluation of the product design by a cross-functional team. Design reviews help identify potential issues, ensure compliance with design inputs, and verify that the design meets the desired requirements. Regular and well-documented design reviews are essential to identify and address design issues in a timely manner.

- Design Verification and Validation: Verification and validation are essential steps in the design control process to ensure that the product meets the intended use and performance requirements. Verification involves checking that the design meets the design inputs, while validation involves testing the product in real-world conditions to confirm its performance. Well-planned and executed verification and validation activities are crucial to ensure the quality and reliability of the final product.

- Design Changes and Document Control: Design changes are inevitable during the product development process. A good design control process should have a robust system in place for managing design changes, including documentation of change requests, impact assessments, and change approvals. Proper document control, including version control and change tracking, is critical to ensure that the correct and up-to-date design documents are used throughout the product development process.

- Risk Management: Risk management is a crucial aspect of the design control process. It involves identifying potential risks associated with the product design and implementing appropriate measures to mitigate those risks. A well-defined risk management process helps identify and address potential issues early in the design process, reducing the risk of product failures or recalls.

- Design History File (DHF): A Design History File (DHF) is a compilation of all the documents and records generated during the product development process. It serves as a comprehensive record of the product’s design history, including design inputs, design outputs, design reviews, verification and validation activities, design changes, and risk assessments. A complete and well-maintained DHF is critical for demonstrating compliance with regulatory requirements and for future reference.

A good design control process is essential for ensuring the quality, reliability, and compliance of products in engineering and manufacturing industries. It should include documented procedures, clear definition of design inputs and outputs, regular design reviews, verification and validation activities, robust change and document control processes, risk management, and a comprehensive Design History File. Implementing a well-defined and robust design control process can help engineering teams streamline their product development efforts, minimize risks, and ensure successful outcomes.